Handicrafts

Carpets

A

carpet is a life-long investment it may well be

the single most expensive purchase during your

trip to Kashmir. Kashmiri carpets are world

renowned for two things they are hand made, never

machine made. And they are always knotted, never

tufted. It is extremely instructive to watch a

carpet being made your dealer can probably arrange

this for you.

An example of Kashmiri

embroidery.

Stretched tightly on a

frame is the warp of a carpet. The weft threads

are passed through, the 'talim' or design and

color specifications are then worked out on this:

a strand of yarn is looped through the warp and

weft, knotted and then cut. The yarn used normally

is silk, wool or silk and wool. Woollen carpets

always have a cotton base (warp & weft), silk

usually has a cotton base. Sometimes however, the

base is also silk in which case you will see that

the fringe is silk; the cost increases

proportionately. Occasionally, carpets are made on

a cotton base, mainly of woollen pile with silk

yarn used as highlights on certain motifs.

When the dealer specifies

the percentage of each yarn used, he is taking

into account the yarn used for the base too.

Therefore, a carpet with a pure silk pile may be

referred to as a '80 per cent silk carpet.' Do not

be alarmed! He is merely stating that the warp and

weft are not of silk.

A third type of yarn,

staple, also referred to as mercerized cotton, is

being mentioned here although it is by no means

traditionally Kashmiri, being a man-made fiber.

Its shine is not unlike that of silk, although in

price it is much lower than silk, but more

expensive than wool. Staple carpets are made to

fill a slot in the market customers demand a

carpet which is not unlike silk in appearance to

blend with their decor of the moment. In a couple

of years they will change their furniture and

furnishings and the staple carpet will have served

its purpose, as such a carpet is neither durable

nor increases in value with time. One important

difference between silk and staple is that pure

silk is far lighter than staple, area for area.

Thus a 3 ft x 5 ft carpet of silk will never weigh

more than 4 kg; one of staple never less than 6

kg.

Carpet weaving in Kashmir

was not originally indigenous but is thought to

have come in by way of Persia. Till today, most

designs are distinctly Persian with local

variations. One example, however, of a typically

Kashmiri design is the tree of life. Persian

design notwithstanding, any carpet woven in

Kashmir is referred to as Kashmiri. The color-way

of a carpet, and its details differentiate it from

any other carpet. And while on the subject of

color, it should be kept in mind that although the

colors of Kashmiri carpets are more subtle and

muted than elsewhere in the country, only chemical

dyes are used vegetable dyes have not been

available now for a hundred years.

The knotting of a carpet

is the most important aspect, determining its

durability and value, in addition to its design.

Basically, the more knots per square inch, the

greater its value and durability. Count the number

of knots on the reverse of a carpet in any one

square inch. It should be roughly the same as the

dealer tells you, give or take 10 knots. The most

common configurations for knots on wool or silk

Kashmiri carpets are 18x 18, 18x20,20x20, 20x22,

or 22x22. A carpet with 18x 18=360 knots per

square inch will obviously cost less than one with

22x22=484. If you are told that a carpet contains

360 knots, and your count indicates about 10 less,

it simply means that the weft has not been evenly

combed down in parts this is not a fault, and

several random checks throughout the carpet will

even out the figure to the dealer's estimate.

Also, there are single and double knotted carpets.

You can quite easily identify one from the other

on the reverse of the carpet. The effect that it

has on the pile, too, is important a double

knotted carpet has a pile that bends when you

brush it one way with your hand, and stands

upright when it is brushed in another direction. A

single knotted carpet is fluffier and more

resistant to the touch: there is no 'right' and

'wrong' side to brush it.

Why make knots at all?

you may ask. It increases the durability

dramatically than had the pile just been looped

through the base and cut. Knotted carpets are

always stiffer and firmer they don't flop or bend

as easily as do tufted carpets.

The points to keep in

mind when choosing a carpet, then, are: - whether

it has been made of silk (pile) on silk (base),

silk pile on cotton base, silk and wool on cotton

base or wool on cotton base: - the number of knots

on the reverse of the carpet: - whether one or

more line in the design has been omitted

completely in which case the pattern looks

lopsided: - whether any element in the design has

been wrongly woven so that one motif is larger or

smaller at one end than the corresponding motif at

another end, or any similar fault: - whether each

motif or element of design has clear. crisp

outlines. Blurred edges indicate a fault In the

weaving. - whether the edges of the carpet are

crooked as if It had been incorrectly mounted on

the frame, so that one end Is broader than

another.

Namdas

Far

less expensive are these colorful floor coverings

made from woollen and cotton fiber which has been

manually pressed into shape. Prices vary with the

percentage of wool, a namda containing 80 per cent

wool being more expenslve than one containing 20

per cent wool. Chain stitch embroidery in woollen

and cotton thread is worked on these rugs.

Papier Mache

At

first glance, all papier mache objects look

roughly the same, and the price differential seems

almost unreasonable. However, besides at least

three different grades of papier mache, some is

actually cardboard or wood! The idea, however. is

not to hoodwink the unwary, but to provide a

cheaper product for someone who wants the look of

papier mache.

To make papier mache,

first paper is soaked in water till it

disintegrates. It is then pounded, mixed with an

adhesive solution, shaped over moulds, and allowed

to dry and set before being painted and varnished.

Paper that has been

pounded to pulp has the smoothest finish in the

final product. When the pounding has not been so

thorough, the finish is less smooth.

Papier mache` table lamp.

The designs painted on

objects of papier mache are brightly colored. They

vary in artistry and the choice of colors, and it

is not difficult to tell a mediocre piece from an

excellent one. Gold is used on most objects,

either as the only color, or as a highlight for

certain motifs, and besides the finish of the

product, it is the quality of gold used which

determines the price. Pure gold leaf, which has an

unmistakable luster, is far more expensive than

bronze dust or gold poster paint. It also has a

much longer life and will never fade or

tarnish.

Varnish, which is applied

to the finished product, imparts a high gloss and

smoothness which in- creases with every

coat.

Cardboard, virtually

indistinguishable from papier mache, gives in

slightly when pressed firmly. Otherwise the only

difference is in the price, cardboard being

cheaper than papier mache.

Chain Stitch And Crewel

Furnishings

Because

of the high quality of embroidery done on wall

hangings and rugs, Kashmiri crewel work is in

great demand throughout the world.

Chain stitch, be it in

wool, silk or cotton, is done by hook rather than

by needle. The hook is referred to as ari, and

quality for quality, hook work covers a much

larger area than needle work in the same amount of

time.

Workers finish a

crewel-embroidered fabric.

All the embroidery is

executed on white cotton fabric, pre-shrunk by the

manufacturers. The intrinsic worth of each piece

lies in the size of the stitches and in the yarn

used. Tiny stitches are used to cover the entire

area the figure or motifs are worked in striking

colors; the background in a single color, made up

of a series of coin sized concentric circles which

impart dynamism and a sense of movement to the

design. Stitches ought to be small, even sized and

neat. The background fabric should not be visible

through the stitches.

Crewel is basically

similar to chain stitch. It is also chain stitch

done on a white background, but here the motifs,

mainly stylized flowers, do not cover the entire

surface, and the background is not embroidered

upon. Wool is almost invariably used in crewel

work and colorways are not as elaborate as in

chain stitch, two or three colors being the norm

here. This fabric is available in bolts, and is

sold by the length. They make excellent household

furnishings being hand or machine washable.

Saffron, Walnuts,

Almonds, Honey

Pampore,

outside Srinagar, is the only place in the world

besides Spain where saffron is grown. The crocus

sativus which blooms for a brief month in the

year, has six golden stamens and one crimson one.

It is the crimson stamen which when collected and

dried is referred to as the most expensive spice

in the world. Sealed jars of this spice, with the

government laboratory's stamp of approval, are

available all over Srinagar. When buying loose

saffron, sampling one strand is enough, for the

flavor and fragrance of saffron are unmistakable.

The climate of Kashmir is

ideal for walnut and almond trees which grow here

in abundance. Natural honey too, is a produce of

the apiaries which abound in the state.

Silks, Tweeds

Sericulture

and tweed weaving are important industries in

Kashmir, with departments of the state government

closely monitoring the process. Interestingly,

just as little or no raw material for tweed comes

from Kashmir, almost no weaving and printing of

silk is done in the state. However, the cocoon

reared in Kashmir is of a superior quality,

yielding an extremely fine fiber, and any silk

woven from this thread becomes known, quite

legitimately, as Kashmiri silk. The fineness of

the yarn lends itself particularly well to the

weaves known as chinon and crepe de chine. in

addition to the universally recognized silk weave.

The cost of silk fabric goes up with its weight

per meter, 30 grams being at one end of the scale

and 80 grams at the other. Fabric is generally

sold by the length as saris and its lightness and

softness lends itself well to shirting and dress

material.

Tweed on the other hand

is woven in Kashmir with pure, never blended, wool

. The resultant fabric, made with imported

know-how, compares favorably with the best in the

world. It is available by the length; occasionally

as ready to wear garments.

Pherans

This

garment, somewhere between a coat and a cloak, is

eminently suited to the Kashmiri way of life,

being loose enough to admit the inevitable brazier

of live coals which is carried around in much the

same way as a hot water bottle. Men's pherans are

always made of tweed or coarse wool: women's

pherans, somewhat more stylized. are most commonly

made of raffel. with splashes of ari or hook

embroidery at the throat, cuffs and edges. The

quality of embroidery and thickness of the raffel

determines the price.

The richly embroidered

'neck' of a pheran.

Shawls

There

are three fibers from which Kashmiri shawls are

made wool, pashmina and shahtoosh. The prices of

the three cannot be compared woollen shawls being

within the reach of the most modest budget, and

shahtoosh being a once-in-a-lifetime

purchase.

Woollen shawls are

popular because of the embroidery worked on them

which is special to Kashmir. Both embroidery and

the type of wool used causes differences in the

price.

Wool woven in Kashmir is

known as raffel and is always 100 per cent pure.

Sometimes blends from other parts of the country

are used and Kashmiri embroidery is worked on

them. These blends contain either cashmilon,

cotton, or a mixture of both. Many kinds of

embroidery are worked on shawls 'sozni' or

needlework is generally done in a panel along the

sides of the shawl. Motifs, usually abstract

designs or stylized paisleys and flowers are

worked in one or two, occasionally three colors,

all subdued. The stitch employed is not unlike

stem stitch, and only the outline of the design is

embroidered. The fineness of the workmanship and

the amount of embroidery determines the value of

the shawl.

Sozni is often done so

skillfully that the motif appears on both sides of

the shawl each side having a different colorway.

This naturally has a bearing on the cost.

Another type of needle

embroidery is popularly known as 'papier mache'

work because of the design and the style in which

it is executed. This is done either in broad

panels on either side of the breadth of a shawl,

or covering the entire surface of a stole. Flowers

and leaves are worked in satin stitch in bright

colors such as those of papier mache and each

motif is then outlined in black.

A third type of

embroidery is ari or hook embroidery; motifs here

are the well-known flower design finely worked in

concentric rings of chain stitch.

Pashmina is unmistakable

for its softness. Pashmina yarn is spun from the

hair of the ibex found at 14,000 ft above sea

level. Although pure pashmina is expensive, the

cost is sometimes brought down by blending it with

rabbit fur or with wool. It is on. pashmina shawls

that Kashmir's most exquisite embroidery is

worked, sometimes covering the entire surface,

earning it the name of 'jamawar'. A jamavar shawl

can, by virtue of the embroidery, increase the

value of a shawl three-fold. Not all pashmina

shawls, however, have such lavish embroidery some

are embroidered on a narrow panel bordering the

four sides of a shawl, others in narrow strips

running diagonally through the shawl.

A second, less frequently

seen weave, done only on pashmina, covers the

surface with tiny lozenge shaped squares, earning

it the delightful name of 'chashme bulbul,' or eye

of the bulbul. As this weave is a masterpiece of

the weaver's art, it is normally not embroidered

upon.

Shahtoosh, the legendary

'ring shawl' is incredible for its tightness,

softness and warmth. The astronomical price it

commands in the market is due to the scarcity of

the raw material. High in the plateaus of Tibet

and the eastern part of Ladakh, at an altitude of

above 5,000 meters, roam Pantholops Hodgsoni, or

Tibetan antelope. During grazing, a few strands of

the downy hair from the throat are shed and it is

these which are painstakingly collected until

there are enough for a shawl.

Yarn is spun either from

shahtoosh alone, or with pashmina, bringing down

the cost somewhat. In the case of pure shahtoosh

too, there are many qualities the yarn can be spun

so skillfully as to resemble a strand of silk. Not

only are shawls made from such fine yarn extremely

expensive, they can only be loosely woven and are

too flimsy for embroidery to be done on them.

Unlike woollen and pashmina shawls, shahtoosh is

seldom dyed that would be rather like dyeing gold!

Its natural color is mousy brown, and it is, at

the most, sparsely embroidered.

Basketry

Willow

rushes that grow plentifully in marshes and lakes

in Kashmir are used to make charmingly quaint

objects, ranging from shopping baskets and

lampshades to tables and chairs, all generally

inexpensive. To increase their life-span,

unvarnished products should be chosen and

frequently sprayed with water, particularly in

hot, dry climates, to prevent them becoming

brittle.

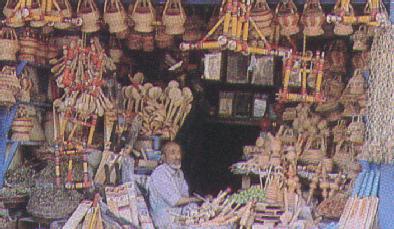

A local crafts shop in

the old city.

Walnut Wood

Kashmir

is the only part of India where the walnut tree

grows. Its color, grains and inherent sheen are

unique and unmistakable, and the carving and

fretwork that is done on this wood is of a very

superior quality.

There are two types of

walnut trees the fruit bearing species whose wood

is so well-known, and one which bears no fruit and

is locally known as 'zangul.' Zangul has none of

the beauty of walnut wood, being much less strong

and possessing no grain, and will not be dealt

with here.

The walnut root is almost

black, and the grain here is much more pronounced

than the wood of the trunk which is lighter in

color. The branches have the lightest color, being

almost blonde, and have no noticeable grain. The

intrinsic worth of the wood from each part of the

tree differs that from the root being the most

expensive, and the branches having the lowest

value.

Often, when a tree is

sawn, a marked difference in color is noticed

between one part of the trunk and the other. This

is overcome by dyeing the lighter part to the

exact shade of the darker. Dye is prepared from

the outer covering of the fruit of the walnut.

Sometimes small objects of utility trays, bowls

and the like are left with the natural variation

of color for customers who find it appealing.

As the grain on any wood

is its distinguishing feature, when a walnut tree

is sawn, the prime motive is to display to full

advantage its densely packed rings. After a tree

is felled, the ideal period for which it should be

left to season is two years. The advantage of

seasoning is that molecules of moisture which are

entrapped in the wood of the live tree evaporate

so that shrinking takes place before the wood is

cut and fashioned into objects for sale.

When a dealer buys a

whole tree and leaves it to season, a part of his

capital becomes blocked for that period and this

will naturally be reflected in the cost of his

product. A cheaper product, on the other hand, is

liable to warp, or in case it is taken to warmer

climes, will crack or shrink.

Knots on any tree are

natural and inevitable, but as their appearance is

commonly thought to mar the beauty and smoothness

of the finished product, knots are usually

concealed skillfully in the sawing, as it is

difficult, though not impossible, to mask them

while carving.

Carving is a

demonstration o. the carver's skill, and walnut is

eminently suitable for this, being one of the

strongest varieties of wood. There are several

varieties of carving deep carving, usually with

dragon and lotus flower motifs, two inches deep or

more; shallow carving, half an inch deep done all

over the flat surface; open or lattice work,

usually depicting the chinar motif: and most

popularly, semi carving, which is a thin panel

along the rim of the surface, with perhaps a

center motif. The advantage of semi-carving is

that it allows the grain of the wood to be

displayed, together with the carver's skill.

Naturally deep carving with all the skill and

labor required, is the most expensive.

Wax polishing brings out

the sheen inherent in walnut wood, and is by far

the most popular finish. Because varnish obscures

the grain of the wood and alters its hue, it is

seldom used.

When choosing objects

made from walnut wood, keep in mind that the type

of carving and part of the tree used will affect

the price.

The optimum thickness for

items of furniture is one inch. Anything less than

that will naturally be less expensive as it

shortens the life of the object. Furniture which

makes exclusive use of walnut wood will naturally

cost more than articles in which zangul has been

used for surfaces normally hidden from view.

Copper and Silverware

The

old city abounds with shops where objects of

copper line the walls, the floor and even the

ceiling, made generally for the local market.

Craftsmen can often be seen engraving objects of

household utility samovars, bowls, plates and

trays. Floral, stylized, geometric, leaf and

sometimes calligraphic motifs are engraved or

embossed on copper, and occasionally silver, to

cover the entire surface with intricate designs

which are then oxidized, the better to stand out

from the background. The work, known as 'naqash',

determines the price of the object, as does the

weight.

|

No one has commented yet. Be the first!